I get lots of questions about what to put on sliders. Here is the latest installment in the blog about the topic. Today’s video shows a newish category to the industry. Known as panel track systems, gliding panels or other proprietary names, they are making a pretty large dent in the market. They are made in two specific ways. Most of the industry has multiple track systems at the top that hold as many panels. For example, a 5 panel system will use 5 tracks in the headrail. Each panel of fabric is attached at the headrail and passes the other panels while a catch is employed to “grab” the next panel. If you watch the video, you will see the general idea.

The type of panel system used in the video is the Hunter Douglas Skyline Panel. It uses a different type of system. Only two rails are used no matter how wide the unit. Each panel is attached at the front and rear rail. This way, as each panel is stacked back, it stacks on top of every other panel. With the Hunter Douglas system, the size of the overlap changes as different panel configurations are used, whereas with the traditional panel systems the panel overlap is very consistent.

Here is how that works: With a traditional panel track system they take the overall width and divide by the number of panels and add the overlap width to each panel. With the Hunter Douglas Skyline system, the customer chooses one of two panel sizes, either 11 1/2″ or 17″ and then they compute the amount of overlap needed to make it all fit in the track size. Which one is a better system is a subject for debate. I have that conversation with all my clients prior to ordering these panel track systems.

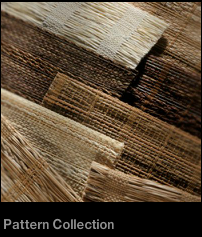

The video shows a solar screen as the material choice, but keep in mind that you can also use a very large assortment of sheer, semi-opaque or completely opaque (blackout) fabrics. Also available are those popular natural woven materials, like bamboo, matchstick, grasscloth and other attractive materials.